Lighting for the food & beverage industry

Lighting for the beverage & food industry - DIN 10500 compliance (HACCP/IFS/BRC)

An important aspect that is often neglected in the production of food and beverages is lighting. Yet appropriate, high-quality lighting plays a decisive role, especially in the food industry. Because only with optimal lighting can possible contamination, damage or sources of error be efficiently detected and eliminated.

In the food industry, good lighting is essential to ensure high product quality. Dark areas or shadows can hide impurities or faulty production processes. Uniform lighting ensures that all areas are clearly visible and potential risks can thus be detected at an early stage. In this context, the colour temperature of the lighting also plays an important role. A neutral, natural colour rendering is advantageous for detecting discolouration or irregularities.

High-quality lighting is also of great importance in the beverage industry. Here, not only production rooms but also storage areas need to be appropriately illuminated.

Compliance with HACCP (Hazard Analysis and Critical Control Points) and IFS (International Featured Standards) standards is thus essential for companies in the food and beverage industry. Proper lighting plays an important role in identifying potential sources of contamination and minimising the risk of contamination. DIN 10500 therefore regulates in detail the requirements for lighting in areas where food or beverages are produced, processed or stored.

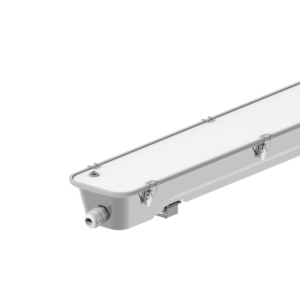

Discover our LED luminaires for the food & beverage industry

Configure your LED lighting

For a DIN 10500 (HACCP/IFS/BRC) compliant configuration, please select the RayLine Eco V3 with the opal optics.

-

Lisa Ortner

Internal Sales - +49 8033 4954-701

- l.ortner@tempLED.de

Hello, I am Lisa your personal consultant

… and I look forward to your contact.

If we could inspire you for our LED industrial lighting and services, we are looking forward to get in touch with you personally. Together we will find the optimal lighting solution for you – let’s get started right away!

What is the HACCP concept?

The HACCP concept is based on seven clear principles that must be observed when developing and implementing an effective HACCP system:

Systematic analysis identifies potential hazards that can occur in the individual production stages. This also includes hazards that can arise from lighting in the food and beverage industry, such as light bulb breakage or contamination by dirt particles.

This phase identifies those points in the production process where control is necessary to prevent, eliminate or reduce hazards. In terms of lighting, for example, this could be the regular cleaning of lamps or the use of shatterproof light sources.

Clear criteria are set to determine whether a CCP is under control or not. For example, limits for lighting in the beverage industry could specify that luminaires must not exceed certain brightness or colour values.

Monitoring measures are established to ensure that CCPs are effectively controlled. This could include regular inspection of lighting systems for proper operation and hygiene.

Should a CCP fail to meet the established limits, appropriate corrective action will be taken to ensure the safety of the end product. This could include, for example, replacing defective luminaires or cleaning dirty lighting systems.

Regular audits of the HACCP system are used to evaluate the effectiveness of the measures and make any necessary adjustments. This could include, for example, an annual audit of the lighting systems to ensure that they are functioning properly and hygienically.

All steps and measures within the framework of the HACCP system must be documented. This also includes records on the lighting systems, such as maintenance logs or hygiene plans.