Cleanroom lighting

Ideal LED lighting for clean rooms

Our cleanroom luminaires and cleanroom luminaires are ideal for use in laboratories, medical practices, hospitals and chip manufacturing.

We are manufacturer

Modularity as a fundamental principle

Recycling rate > 90%

Magnets for tool-free one-man assembly

Injected polyurethane foam gasket

Safety glass with screen printing frame

Products for clean room lighting

Catalogue

Download the current catalogue for cleanroom lighting.

Application folder

Download the latest application folder.

More products for full equipment

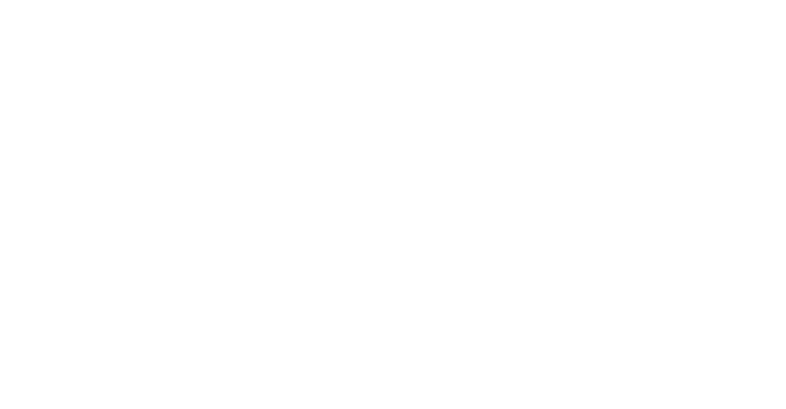

Cleanroom luminaires

Are you looking for a new cleanroom luminaire? With our LED cleanroom luminaire tempLED RayClean Pro V2 you will find exactly the right LED lighting for your cleanroom. Our cleanroom luminaires are subject to DIN EN ISO 14644-1 standards and constant quality control. Thus tempLED is exactly the right partner for the production of cleanrooms of ISO classes 2 to 6. RayClean Pro V2 is also available in 2 power levels 39 and 54 watts and can thus shine in many different applications. These include laboratories, medical practices, hospitals and also chip production.

Clean room luminaires

Our cleanroom luminaire tempLED RayClean V2 is perfectly suited for cleanrooms of ISO classes 8 as well as 9 and comes in 2 power levels 39 and 54 watts. In addition, it convinces by the simple ceiling and wall mounting. Thus, our cleanroom luminaire is the ideal partner for lighting in hospitals, patient rooms or the beverage and food industry.

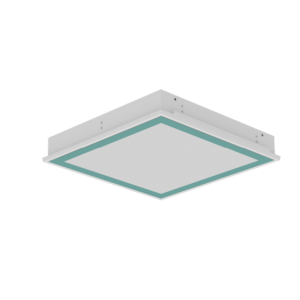

LED retrofit without expensive recertification

You want to convert or retrofit your already existing and certified lighting? For this particular application, we offer the perfect solution with our tempLED RayClean Kit. In a simple one-man installation, you can replace your existing conventional cleanroom luminaire thanks to the strong magnetic mounting points. Since you only replace the luminaires in the existing housing, there is no need for the otherwise very expensive recertification of your cleanroom.

Distinction RayClean Pro & RayClean

| Clean room RayClean Pro | Controlled area RayClean | |

|---|---|---|

| Which standards does tempLED meet? | DIN EN ISO 14644-1 Classes 2-6 | VDA 19 (ISO 16232) |

| Structural differentiation of the tempLED luminaires |

- Modular system support - Antibacterial sealing foam throughout |

- System support integrated

in luminaire housing - Continuous sealing foam |

| Technical differentiation of the tempLED luminaires | IP 65 | IP 30 |

Clean room class tables - standard according to DIN EN ISO 14644-1

| particles per m³ | |||||||

|---|---|---|---|---|---|---|---|

| Class | 0,1 µm | 0,2 µm | 0,3 µm | 0,5 µm | 1,0 µm | 5,0 µm | |

| ISO 1 | 10 | clean room | not on sale | |||||

| ISO 2 | 100 | 24 | 10 | clean room | on request | |||

| ISO 3 | 1.000 | 237 | 102 | 35 | clean room | on request | ||

| ISO 4 | 10.000 | 2.370 | 1.020 | 352 | 83 | clean room | on request | |

| ISO 5 | 100.000 | 23.700 | 10.200 | 3.520 | 832 | clean room | on request | |

| ISO 6 | 1.000.000 | 237.000 | 102.000 | 35.200 | 8.320 | 293 | clean room | tempLED Standard |

| ISO 7 | 352.000 | 83.200 | 2.930 | clean room | tempLED Standard | |||

| ISO 8 | 3.520.000 | 832.000 | 29.300 | controlled area | tempLED Standard | |||

| ISO 9 | 35.200.000 | 8.320.000 | 293.000 | controlled area | tempLED Standard | |||

Cleanroom standard according to VDA 19.2

| Cleanliness levels | Definition / Delimitation | Marking |

|---|---|---|

| 0 | There is no separation or air filtering. | None |

| 1 | Work processes are separated from each other by markings or partitions. Particles are not filtered out of the air. | Controlled area |

| 2 | Work processes take place in structurally delimited premises. Particles are not filtered out of the air, but fall to the floor and onto surfaces. | Controlled area |

| 3 | Work processes take place in structurally delimited premises. People and materials only enter the room via airlocks. Particles are filtered out of the air. | Clean room |

-

Isabella Bechtler

Internal Sales - +49 8033 4954-690

- i.bechtler@templed.de

Hello, I am Isabella your personal consultant

… and I look forward to your contact.

If we could inspire you for our LED industrial lighting and services, we are looking forward to get in touch with you personally. Together we will find the optimal lighting solution for you – let’s get started right away!